| Details: |

Hydrocarbon Resins are made from petroleum based feedstocks either aliphatic (C5), aromatic (C9), DCPD (dicyclopentadiene), or mixtures of these. There are three basic categories of hydrocarbon tackifier resins, some with several sub-categories.

C5, Aliphatic Resins are so named because they are generally polymers of monomers with five carbons. Basic C5 aliphatic resins have Gardner colors between 1.5 and 6 (from light yellow to light brown) and are mostly used to tackify aliphatic polymers, especially natural rubber, EVA, SIS and APO.Petroleum resin for solvent based pressures sensitive adhesi are low molecular weight aliphatic petroleum resins that widely applicable to solvent based pressure sensitive adhesive labels and tapes. These grades have great compatibility with SIS, caouthouc, synthetic rubber of various kinds, EVA. As well as enhanced all kinds of performances in solvent based pressure sensitive adhesive applications.

Hydrogenated C5, Aliphatic Resins are basic C5 hydrocarbon tackifers that have been hydrogenated to improve their color and thermal stability.

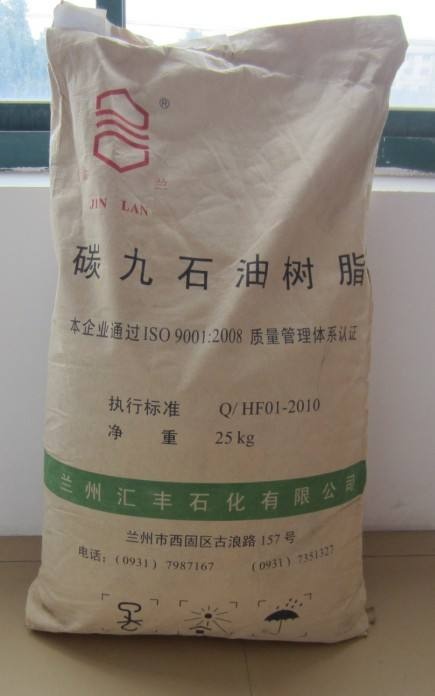

C9, Aromatic Resins are so named because they are generally polymers of nine-carbon aromatic monomers. They are based on aromatic feedstocks that undergo very little refining prior to the polymerization of the resin. They are usually dark in color within typical Gardner color of 6 to 10 (dark yellow to dark brown). They are used mainly in EVA-based adhesives, contact adhesive for footwear, printing inks, sealants, and paints. C9 liquid resins are especially useful in flooring adhesives. As a class, C9 resins have a distinctive aromatic odor. There are two sub-categories of C9 aromatic tackifiers, each with distinctive properties.

Hydrocarbon resin is a C5/C9 aromatic hydrocarbon used in industrial applications. It has a tackifying effect and is suitable for use in paint, printing ink, adhesives, rubber and other areas where tackiness is required.

C9 Petroleum resin is a kind of thermal plasticizing resin produced by C9 fraction,by-products of petroleum cracking, through pretreatment,polymerization and distillation, It is not a high polyer bat a low polyjer with the molecular weight between 300-3000. Featured by acid value, easy mutual solubilities, resistant to water, resistant to ethanol and chemicals. It has the chemical stabilizing property to acid and alkaline, viscosity adjusting and thermal stabilizing, Generally, the petroleum resins are not used independently, but have to be used together with other kinds of resins as promoters, adjusting agents and modifiers in hot-melt adhesive, pressure-sensitive adhesive, hot melt road marking paint, rubber tires and so on.

This series are thermoplastic resins, obtained from polymerizing unsaturated aromatic petroleum feedstock. They are clear yellowish resins, soluble in most industrial solvents, and particularly in aromatic and aliphatic ones. Wide compatibility with different polymers and resins makes the series excellent multi-purpose products.The major applications areas are paints and varnishes, printing inks, adhesives, rubber and elastomers, etc. Remark: For detailed technical specification sheet and material safety data sheet, please contact our sales area manager respectively. |

| Related Products : |

C5 Petroleum Hydrocarbon Resin

C5 Petroleum Hydrocarbon Resin

Gum Rosin

Gum Rosin